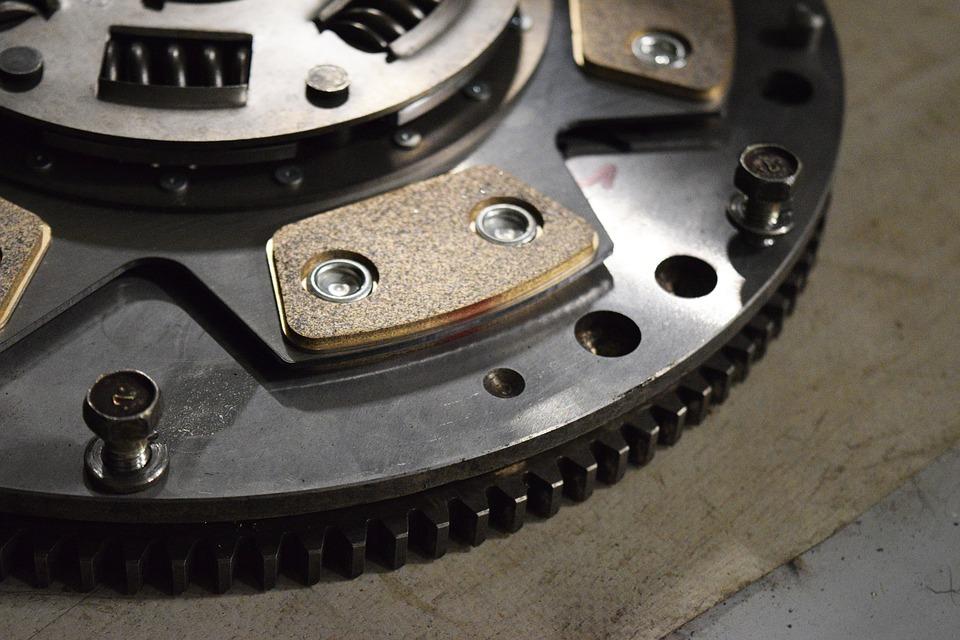

Flywheel Resurfacing

Smooth Power Transfer Starts with a Resurfaced Flywheel

At Saggu Industries, we provide expert flywheel resurfacing services to restore surface integrity, eliminate hot spots, and ensure smooth clutch engagement. Whether you’re replacing a clutch, repairing engine performance issues, or rebuilding a transmission system, resurfacing the flywheel is a crucial step to prevent slippage, vibrations, and uneven wear.

Our team handles everything from standard automotive flywheels to heavy-duty industrial and diesel applications, delivering precision-machined results every time.